News

QA1 Launches New Line of GM Tubular Control Arms

QA1 is excited to announce the introduction of our next generation control arms for popular GM muscle cars. Control Arm 2.0 is offered in three configurations for the specific needs of street performance, pro touring, and drag racing.

These control arms were designed with four things in mind: strength, weight savings, drivability improvement and great looks. To achieve all of this, the arms are constructed with high strength tubing, billet 7075 aluminum cross shafts, and integrated ball joints. Consumers can expect a 25% weight savings over factory with the upper arms weighing only 7 lbs. and the lower arms weighing just 10 lbs. They are among the lightest and strongest control arms on the market.

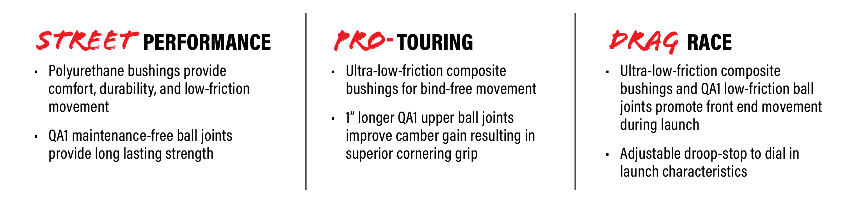

In addition to improved geometry, each configuration has unique features to optimize performance for the intended use.

- Street Performance – Drivers will appreciate improved handling, a smooth ride, and bind-free suspension movement from polyurethane pivot bushings. Long-term strength and durability come from QA1’s maintenance-free ball joints which are pre-installed in every arm.

- Pro-Touring – Handling and overall cornering grip were taken to the next level using QA1’s low-friction ball joints with 1” longer ball joint studs. Eliminating unwanted flex while promoting bind-free movement is accomplished with the use of ultra-low-friction composite bushings.

- Drag Race – Off the line, racers can now tune their launch characteristics through an adjustable droop stop. Improved weight transfer and bind-free movement comes from QA1 low-friction ball joints and ultra-low-friction composite bushings.

“These arms are a perfect example of optimizing a product design to address real-world consumer needs,” says Chuck Olson, QA1 VP of Engineering. “They are designed to be paired with QA1 Pro Coil Systems and provide remarkable drivability improvements for classic GM muscle cars.”

“We are so excited to offer these new control arms,” says Melissa Scoles, QA1 President. “Our customers regularly ask us about how they can reduce weight on their vehicles and these arms are the perfect product to help with that.”

The new designs take advantage of QA1’s expansive design and manufacturing capabilities in our new state-of-the-art facility in Lakeville, Minnesota. Robotically welded for precision and maximum strength, these arms are unmatched, giving customers the highest quality product for their ride.

Available now, the arms can be purchased as a set or as part of QA1’s full-vehicle suspension kits. Enter your vehicle on QA1’s website to see what parts are available for your ride and easily find a dealer to purchase yours today.

*******************************************

About QA1

Motivated by the idea that experiences were best made behind the wheel, QA1 manufactures high performance suspension and driveline designed for those who #goDRIVEit.

Founded in 1993, QA1 is an industry leader in performance shocks, suspension components, composite driveshafts, rod ends, spherical bearings and related accessories for the motorsports and industrial markets. QA1 has more than 100,000 square feet of office and manufacturing space in Lakeville, Minnesota. The state-of-the-art facility includes a complete line of CNC machines, hydraulic presses, filament winding and laser cutting equipment that permit all-inclusive shock absorber, suspension component and composite driveshaft manufacturing and assembly operations. QA1’s quality system is certified to the ISO 9001 standard.

For additional information and a free catalog, call 800.721.7761 or visit QA1’s website at www.QA1.net.