Whitepapers & Articles

WHITE PAPERS

Improved Performance of Filament-Wound Composite Drive Shafts with Next Generation Inorganic Nanoparticle-Filled Epoxy Resins

Previous work explored the impact of high matrix modulus on the design and performance of filament wound drive shafts. In the present study, next generation inorganic nanoparticle-filled epoxy matrix resin is shown to improve the strength of filament-wound composite drive shafts.

Integrating Custom Shock Absorbers into Motion Control Systems

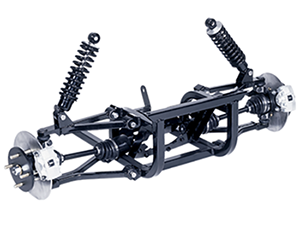

When most people think about shock absorbers, the first thing that comes to mind is the ones bolted on the four corners of their vehicle. The role of shocks in this application is to absorb bumps without transferring the jolt to the passengers, allowing the driver to confidently steer through curves without excessive body roll. This same force-damping technology can be incorporated into many designs beyond automotive applications to provide optimal performance for various motion control applications.

Carbon Composite Driveshaft: Tailorable Performance

Every gearhead knows that the transfer of power from an engine to the axle and drive wheel in a rear-wheel drive vehicle requires a driveshaft, and that this highly loaded part is typically made of steel or aluminum. When composites became more widely available in the early 1980s, carmakers recognized that a carbon fiber composite driveshaft could bring significant benefits unavailable with metal designs, and several production vehicles were so equipped through the early 2000s. Yet, in some corners, composite driveshafts never went away, and there are numerous manufacturers who have prospered making shafts for race cars, hot rods and specialty applications.