Carbon Fiber Tubing

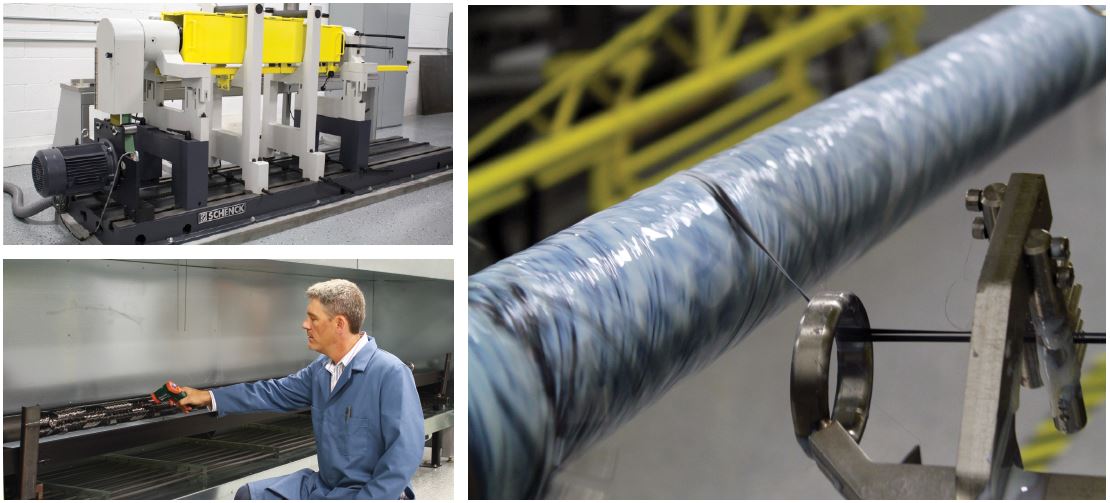

QA1 can take your concept utilizing carbon fiber tubing from initial design to full production, all at our facility in Lakeville, MN.

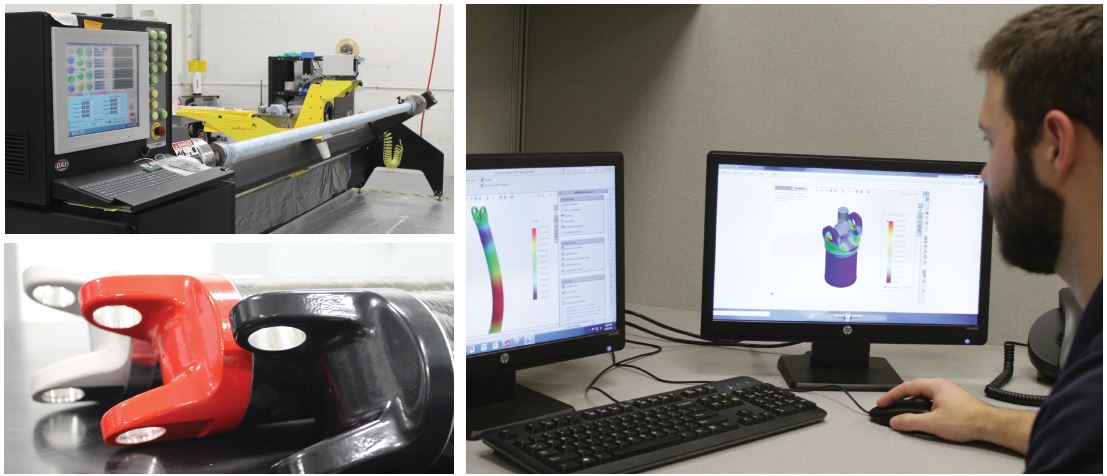

Working with advanced composites and utilizing state-of-the-art in-house equipment, we will design and manufacture the superior products you need. While our carbon fiber driveshafts have set new standards in the motorsports industry, we also make custom composite materials and shapes out of carbon fiber, S-glass, E-glass, aramid fiber, and more. We optimize componenets for high torque, high critical speed, and low NVH to provide stronger, better-performing products for you and your customers.

Ready to see if carbon fiber or other advanced composites are right for your project?

How We Can Assist You

- Application and design engineering (3D modeling, simulation, prototyping)

- Testing and product validation (balance, torsion, NVH, tension, bending)

- Manufacturing and quality control (ISO 9001, component traceability)

Custom Carbon Fiber And Composite Solutions Suitable for a Variety of Industries

We have the capabilities to design and manufacture carbon fiber tubing and shapes for a variety of applications in industrial markets such as:

We have the capabilities to design and manufacture carbon fiber tubing and shapes for a variety of applications in industrial markets such as:

- Cooling towers

- Windmills

- Paper mills

- Printing presses

- Oil rigs

- Irrigation systems

- Treatment plants

- Experimental aircraft

- Steel-processing equipment

- Auxiliary pumps

- Refuse trucks

- Tractors

- Combines

- Military and defense

Case Studies

Application: Dirt Late Model Carbon Fiber Driveshafts

Application: Dirt Late Model Carbon Fiber Driveshafts

Challenge: Create a carbon fiber driveshaft that handles the abuse of dirt late model racing while optimizing torsional performance for more traction and increasing driver safety.

Solution: Satisfied the requirements of both racers and sanctioning bodies with a unique wind angle for high RPM stability, optimal rigidity and extreme torque capacities.

Incorporated a specialized co-engineered 3M™ resin for improved abrasion resistance and tube longevity. The resin also contributed to the shaft’s higher compressive strength and resistance of water absorption for increased torque capacity and traction.

Product: 2.25” TractionTwist™ Carbon Fiber Driveshaft

Application: Experimental Aircraft

Application: Experimental Aircraft

Challenge: Develop a long-span, lightweight propeller shaft for prototype aircraft.

Solution: Utilized existing technology that met all design and safety specifications to create a custom carbon fiber driveshaft while minimizing R&D costs for the customer.

Product: Custom carbon fiber propeller shaft and tooling development

Application: Test Stand Dynos

Challenge: Develop a long-span, lightweight propeller shaft for prototype aircraft.

Solution: Starting with computer simulation, a custom driveshaft was engineered that utilized a custom wind and dimensions to avoid the undesired frequencies. Modal analysis then proved the final product before moving into final production.

Product: Custom driveshaft and tooling

Accolades

- Award for Composites Excellence (ACE) from the American Composites Manufacturers Association (ACMA) for Materials and Process Innovation. Read more.

- Composites and Advanced Materials Expo (CAMX) Outstanding Technical Paper Award for the 3M co-authored whitepaper titled, Improved Performance of Filament-Wound Composite Drive Shafts with Next Generation Inorganic Nanoparticle-Filled Epoxy Resins. Read the paper here.

- 2016 SEMA Global Media Award for its REV™ Series carbon fiber driveshafts. Read more.

- 2014 SEMA Global Media Award for its REV™ Series carbon fiber driveshafts. Read more.

See our resources page for more whitepapers and tools.