A LEADING MANUFACTURER FOR INDUSTRIAL AND OE APPLICATIONS

Founded in 1993, QA1 is an industry leader in shock absorbers, suspension components, composite driveshafts, rod ends, spherical bearings and related accessories for motorsports and industrial markets.

QA1 has more than 100,000 square feet of manufacturing and office space in Lakeville, Minnesota. We specialize in the development of motion control sub-assemblies and complete suspension systems. Our team can also develop individual components to enhance existing designs. Our state-of-the-art facility includes a complete line of CNC machines, hydraulic presses, filament winding and laser cutting equipment to permit all-inclusive shock absorber, suspension component and composite driveshaft manufacturing and assembly. QA1’s quality system is certified to the ISO 9001 standard.

Email OEInfo@QA1.net or call 952-444-4093 to see how we can develop solutions tailored to your application.

OUR AREAS OF EXPERTISE

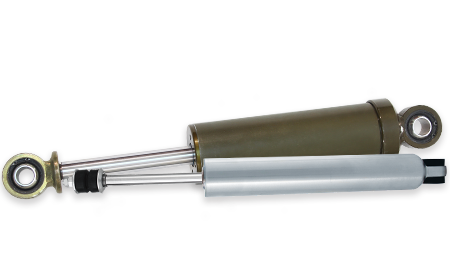

SHOCK ABSORBERS

With a long history of designing and manufacturing shocks for performance motorsports, we apply our knowledge and technology to industrial dampers and motion control solutions. We manufacture twin tube and monotube shock absorbers in a variety of sizes, mounting configurations and valving options. We can also identify vendors to offer more economical solutions. Every characteristic can be tailored to your application, optimizing your product with customized valving and spring combinations.

With a long history of designing and manufacturing shocks for performance motorsports, we apply our knowledge and technology to industrial dampers and motion control solutions. We manufacture twin tube and monotube shock absorbers in a variety of sizes, mounting configurations and valving options. We can also identify vendors to offer more economical solutions. Every characteristic can be tailored to your application, optimizing your product with customized valving and spring combinations.

ROD ENDS & BALL JOINTS

We have rod ends, ball joints and linkages for a wide range of industries, from Lawn & Garden to Agriculture and beyond. We are a leader in rod ends and spherical bearings, with over 1,500,000 units sold annually. Our large selection, economical prices, unmatched quality and huge inventory with same-day shipments ensure you'll find a solution that meets your needs. If we don't stock it, we can develop products to meet your specifications. This includes custom rod ends, spherical bearings, linkages, ball joints and more.

We have rod ends, ball joints and linkages for a wide range of industries, from Lawn & Garden to Agriculture and beyond. We are a leader in rod ends and spherical bearings, with over 1,500,000 units sold annually. Our large selection, economical prices, unmatched quality and huge inventory with same-day shipments ensure you'll find a solution that meets your needs. If we don't stock it, we can develop products to meet your specifications. This includes custom rod ends, spherical bearings, linkages, ball joints and more.

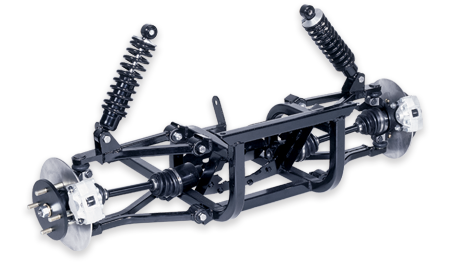

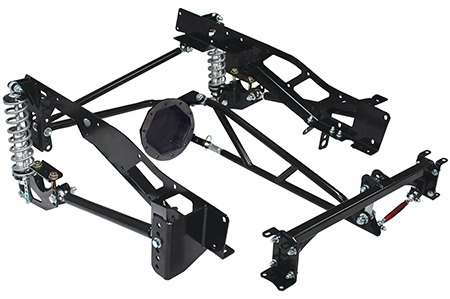

MOTION CONTROL SYSTEMS

We make your project easier by providing a single source for design and manufacturing of custom-fabricated motion management solutions. Whether you need our assistance manufacturing a single component or a full suspension assembly, including custom shock absorbers and carbon fiber components, we will deliver.

We make your project easier by providing a single source for design and manufacturing of custom-fabricated motion management solutions. Whether you need our assistance manufacturing a single component or a full suspension assembly, including custom shock absorbers and carbon fiber components, we will deliver.

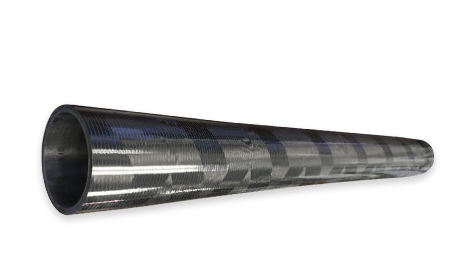

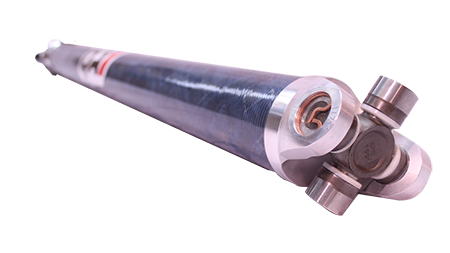

CARBON FIBER TUBING

We can take your carbon fiber concept from initial design to full production, all at our facility in Lakeville, MN. Working with advanced materials and utilizing state-of-the-art in-house equipment, we will design and produce the superior product you need. While our carbon fiber driveshafts have set new standards in motorsports, we also make custom composite tubing and shapes out of carbon fiber, S-glass, E-glass, aramid fiber and other materials.

We can take your carbon fiber concept from initial design to full production, all at our facility in Lakeville, MN. Working with advanced materials and utilizing state-of-the-art in-house equipment, we will design and produce the superior product you need. While our carbon fiber driveshafts have set new standards in motorsports, we also make custom composite tubing and shapes out of carbon fiber, S-glass, E-glass, aramid fiber and other materials.